THE HENRY TEAM

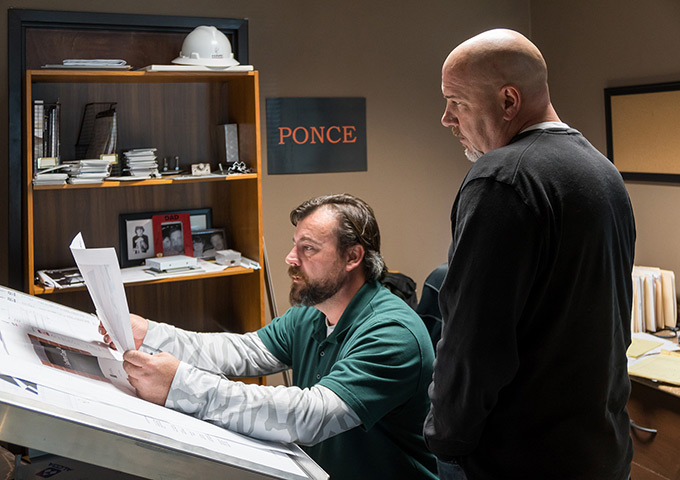

Throughout this website we have stressed that building strong client relationships is central to our business approach. We have emphasized our desire to act as team members, working together with the other principal players on each project, to develop ideal solutions for any challenge that presents itself. Consistently meeting that goal is only possible because of the talent and dedication of the people who make up our in-house team. Consider this section an introduction to these incredible people, and a glimpse into what they are capable of.

For over sixty years the Henry family has focused on two constants: A commitment to the reputation of the company, and a great appreciation for the men and women that make it up. They have always worked to make the company the best it could be: to produce the best products, provide the best service, and be the best partner our clients could hope for.

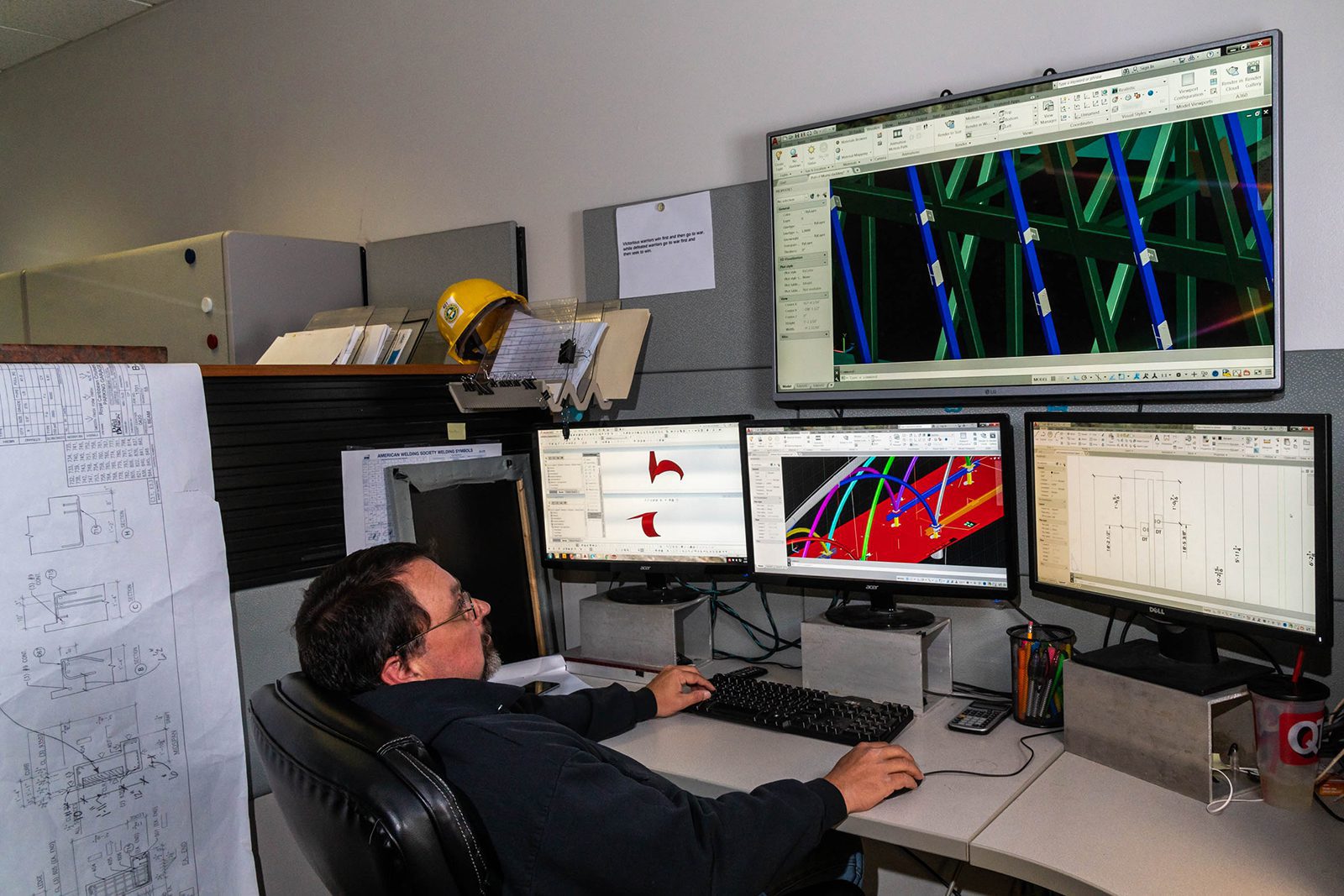

Just as important is the culture they have built within the company. Henry has attracted, and kept, some of the best talent in the industry. This has only been possible because of the Henry’s commitment to providing each employee with room for professional growth, freedom to develop creative solutions, and the best tools and technology possible.